Material Compliance (MC)

Complex requirements clearly structured for easy processing

MAP - Your navigation system for material compliance

I am your personal partner if you are looking for a structured way through the complex world of material compliance requirements.

- Directly to the destination without detours -

The aim of material compliance is to protect people and the environment - I want to support this through my work.

What are the benefits of material compliance?

Material compliance increases the value of your product!

- Protection of employees and the environment

- Increase in the value of the product

- Sustainability / competitiveness / recyclability

- Market and image promotion

- Efficient response to customer inquiries

- Increase in customer satisfaction

- Avoidance of supplier failures / production stops / product recalls

- Legal certainty in claims for damages and audits by the authorities

Your advantages when you work with MAP:

- TÜV certified material compliance officer as partner

- Only ONE contact person

- I share my expertise with you and your employees

- In me you have a reliable and honest partner whom you can trust

- I have 20+ years of professional and industry experience

- The topic of material compliance is close to my heart

What are the problems with the implementation of material compliance requirements in companies?

- Material compliance rules too complex

- Unclear Duties

- Uncertainty in communication in the supply chain

- Unclear responsibilities

- Missing integration of material compliance requirements in business processes

- Lack of expertise

Further information on the subject of material compliance | product compliance

Material Compliance (MC) deals with the observance of environmental and international laws and regulations, religiously motivated requirements and requirements of companies that restrict or even prohibit the use of various substances and / or materials in products.

Translation from https://de wikipedia org/wiki/Material_Compliance

– There are currently 50+ material compliance requirements worldwide

Almost every company in the EU has to deal with the complexity and constant expansion of the MC requirements and, above all, meet them. Primarily, it is a matter of passing on information about the various substances / materials that are used. Everyone is obliged and responsible to comply with the rules and regulations and also to guarantee compliance with the applicable legal restrictions.

One goal of the material compliance regulations and guidelines is to increase the transparency of the materials used, to ensure the provision of material data and, if necessary, the labeling of the corresponding substances.

As an external material compliance officer (TÜV), I support you with the answers for your individual questions, e.g. when processing customer inquiries. I offer you complete solutions for dealing with material compliance issues in your company. Through the targeted analysis of your company, I create a tailor-made concept for you and accompany you in its implementation. So that this does not only take effect temporarily, internal guidelines are created for all business areas concerned so that the MC requirements are also met for new products or product changes. An economically viable implementation is guaranteed through open communication and high transparency of the respective steps.

Background to the REACH regulation

The most extensive set of material compliance regulations is the REACH regulation (EC) 1907/2006. It is the European chemicals regulation for the registration, evaluation, authorization and restriction of chemical substances (Registration, Evaluation and Authorization of Chemicals). The administration for these and other regulations is carried out by the ECHA (European Chemicals Agency).

In the 1960s, with Directive 67/548 / EEC, which dealt with the classification, packaging and labeling of substances dangerous to humans or the environment, the EU made initial efforts to establish uniform regulations for the handling of chemicals.

Primarily, the need to develop regulations and guidelines has been driven by disasters. For example the chemical accident in Seveso in 1976 or the "Bhopal disaster" in 1984. The latter released several tons of toxic substances into the atmosphere. It resulted in an estimated 10,000 deaths and 300,000 injuries. When such accidents occur, it is often not even known what substances are involved and how those affected can be helped.

But as well environmental pollution that caused “acid rain” and polluted water is one of the drivers, as well as manifold problems caused by the improper handling and disposal of chemicals. More and more environmental organizations were formed and the population was made more and more aware.

The biggest problem still arises from the multitude of chemicals existing around the world (1981:> 100,000 substances), for which there is for the most part no risk management and whose hazard potential is largely unknown. Lt. The ECHA does not yet have sufficient data sets for more than 86% of the high-volume production chemicals (2021).

In my opinion, REACH is taking a very hopeful approach.

- Instead of, as was the case in the past, it is no longer the duty of the person concerned or the state to prove the dangerousness of chemicals, but the responsibility for safe production and

use is placed in the hands of the industry.

- “Old” as well as new chemicals must be registered and fundamentally described in the dossiers required for this.

- The resulting dossiers are evaluated by ECHA and the responsible authorities of the respective member states.

- Appropriate investigation of the dangers while minimizing animal testing and costs is sought. Registrants for the same chemicals are requested to share the effort involved in preparing the

dossier.

- The harmonization of the prescribed tests leads to results that can be compared with one another.

- Die Autorisierung führt dazu, das besonders besorgniserregende Stoffe (SVHC’s) Beschränkungen unterworfen oder gar vollständig verboten werden. Es wird dazu gedrängt diese Stoffe zu substituieren.

The aim of REACH is to protect people and the environment - I want to support this through my work.

Material Compliance | Product Compliance Consulting

Consulting Portfolio

Specific support for your individual needs as an external material compliance officer (TÜV):

- Assistance in answering customer inquiries

- Supplier communication concept

- Creation of declarations of conformity

- legally compliant work

- Introduction of relevant key figures

- Training

- and a lot more

- Feel free to ask for further points without obligation

Free introductory meeting

In an initial consultation, I will show you how you can benefit from a secure material compliance workflow and clarify important questions about the process with you.

I will inform you personally:

- Motivation for material compliance

- REACH / RoHS basics

- What benefits does your company gain

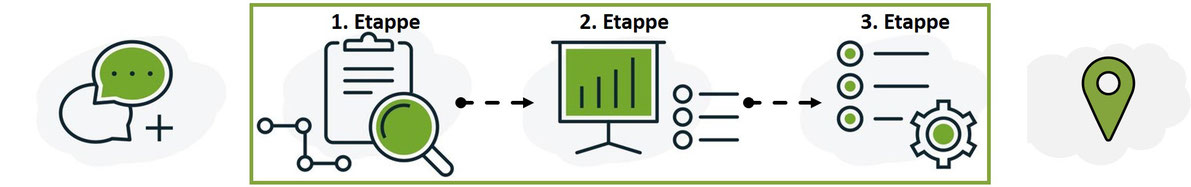

- How do the stages to product conformity go?

- Status analysis

- Concept

- Implementation

- What expenses will your company have to deal with?

Status analysis

I record the current state for you:

- What role (s) does your company play

- In which processes has material compliance been integrated so far?

- What materials and products are there in your company?

- How is your company affected

- Who are your customers

- How do you communicate with your suppliers?

I provide questionnaires and go through them personally with your employees.

Your employees provide the necessary data / information.

I analyze the data.

Concept

I will create an action plan for you:

- Determination of all measures

- Assignment of the measures to the business areas

- Assignment of the measures to the business processes

- Definition of key figures for continuous monitoring

- List of required resources

I will present you the finished concept.

Implementation

I implement the concept together with your employees:

- I train your employees in the business areas concerned

- I pass on my specialist knowledge to your employees

- Your employees implement what they have learnt

I will prepare a final report for you.

You reached your GOAL!

Material compliance describes compliance with all legal requirements that restrict or even prohibit the use of various substances and / or materials in your products.

Your benefit:

- Protection of employees and the environment

- Increase in the value of the product

- Sustainability / competitiveness / recyclability

- Market and image promotion

- Efficient answering of customer inquiries

- Increase in customer satisfaction

- Avoidance of supplier failures / production stops / product recalls

- Legal certainty in claims for damages and audits by the authorities

Als Material Compliance Beauftragte (TÜV) biete ich Beratung, Schulung und Unterstützung für Unternehmen in Baden-Württemberg und Bundesweit an.

Es geht um den Aufbau von Verständnis für Rechtsvorschriften wie z.B. REACH, RoHS und Konfliktmineralien oder auch um eine Status-Analyse, um die relevanten gesetzlichen Pflichten Ihres Unternehmens zu ermitteln.

Im Fokus steht immer eine möglichst unbürokratische Umsetzung der Anforderungen in den bei Ihnen bereits vorhandenen Prozessen.

Gerne unterstütze ich Sie auch bei der Bewältigung Ihres Tagesgeschäfts.

© 2025

As a material compliance officer and physicist, I advise small and medium-sized enterprises (SMEs), e.g. from the metal processing, renewable energy & environment, plastics, mechanical engineering, furniture, sporting goods, textiles and many more in the Rottweil, Freudenstadt, Tübingen, Zollernalbkreis, Tuttlingen, Schwarzwald-Baar, Constance Area and Germany-wide.